1.0 Introduction.

Cellulase, a multicomponent enzyme, (cellobiohydrolase, endocellulase, and ß-glucosidase) responsible for bioconversion of cellulose into soluble sugar [1], are of particular interest in the industrial world and it contributes to 8% of the world industrial enzyme demand for the manufacturing of various products for human and animal consumption [2]. In addition to bioethanol production, the major industrial application of cellulases is in the textile industry for bio-polishing and in the production of detergents for fabric softness and brightness [3].

Cellulases also find application in animal and animal food, agriculture, biomass refining, brewery and wine, pulp and paper, and medical and pharmaceutical industry industries [4,5]. The primary obstacle impeding the industrial application of cellulases are the cost of production and the low yields of the cellulase enzymes [4,5]. Therefore, research into the ability of the lignocellulose hydrolyzing microbial strains to utilize inexpensive substrates, particularly from agricultural waste has become a subject of investigation [6,7].

Wastes are the material that are not needed and are not usable economically with further processing. It may be in the form of solid, liquid, and gas. They originate from the human activities such as agriculture, industry, domestic activities etc [8]. Agricultural waste such as sugarcane bagasse corns tover, corn fiber, rice hulls, rice straw, woody crops, and forest residues are important sources of inexpensive and renewable lignocellulosic biomass for industrial application [6,9,10]. The conversion of hemicelluloses from this biomass into agro-valuable products has been considered strategic for the economic viability and bedrock of lignocellulose biorefineries [11,12]. Sugarcane bagasse constitutes a promising raw material for biorefineries owing to its huge availability as waste in sugarcane mill plants. Sugarcane bagasse is generated, following the extraction of cane juice from the sugarcane stem for sugar or ethanol production [13]. About 270-280 kg of bagasse is generated per ton of sugarcane processed. This bagasse is usually burned to generate the energy required for the process [13] or discarded which in turn constitutes an environmental nuisance.

About 50% of sugarcane bagasse are made up of cellulose, while lignin and hemicellulose equally constituted the remaining 50% component of the bagasse [14]. This agro-waste therefore can be put into valuable use in biorefineries as a carbon source for microbial activities, production of protein-rich animal and livestock feed, bio-enzymes via microbial activities, organic acids, and pharmaceutical compounds [3,14,15].

In the contest of enzyme production, filamentous fungi such as Aspergillus species are particularly important enzyme producers for industrial scale, due to their ease of cultivation, high production level within a short time, and extracellular secretion of enzymes [16,17]. These fungi are known producers of cellulose and hemicellulose degrading enzymes and have been widely explored for the production of industrial relevance enzymes, including cellulase, pectinase, amylases, xylanases, and so on [18,19]. In the present study, we explore the potential of Aspergillus niger and Aspergillus flavus to utilized agro-waste as a carbon source for cellulase production and determine the optimum yielding condition.

2.0 Materials and Methods

2.1 Sample Collection and processing

Soil samples(refuse dump site, sewage sludge, and decayed plantain soil) for the isolation of A. niger and A. flavus were collected from Bosso, Local Govt Area of Minna, Niger State, Nigeria. The agro-waste use as a carbon source including the plantain pseudostem (PS), and corn cob (CC) were collected from Bosso, Local Govt while the sugarcane bagasse (SB) were collected from sugarcane juice processing in Abuja, FCT, Nigeria. Samples were collected in polythene bags and transported to the Laboratory for processing and analysis. The PS, CC, and SB were separately pounded, milled into powder, and stored at room temperature prior to further processing and analysis

2.2 Isolation and identification of microorganisms

The test organisms including A. niger and A. flavus were isolated each of the soil samples from different samples using standard microbiology techniques [20]. A small portion of the mycelia growth from pure fungi isolates were carefully picked with the aid of a pair of sterile inoculating needles and placed in a drop of lactophenol cotton blue on a microscope slide and covered with a cover slip. The slide was examined under the microscope, first with (x10) and then with (x40) objective lens for morphological examination as described by Oyeleke and Manga, [21]. The fungal isolates were identified based on the colour of aerial hyphae and substrate mycelium, arrangement of hyphae, conidial arrangement as well as morphology.

2.3 Qualitative Screening of cellulolytic microbial isolates

A loopful of the pure fungi isolates was inoculated into an autoclaved reaction media [(g/l); peptone, 5.0; yeast extract, 5.0; K2HPO4, 0.2; agar 20.0 and 10.0 carbon source (agro-waste) and incubated for 48 hr at 28±2°C. Carboxyl Methyl Cellulase (CMC) was also added into a similar media to serve as the control. After the incubation period, the plate was flooded with 0.1% aqueous Congo red, washed with 1 M NaCl, and positive isolates were identified based on the zone of hydrolysis [22].

2.4 Quantitative screening of the microbial cellulase production using selected agro-waste as a carbon source

Five gram of each substrate (PS, CC and SB) and CMC (control) was placed in a 250 mL conical flask containing basal media salt solution [(g/l): urea, 0.3; peptone, 0.3; yeast extract, 0.75; (NH4)2SO4, 1.4; KH2PO4, 2.0; CaCl2, 2.0; MgSO4.7H2O, 0.3; NaNO3, 3.0; CaCl, 0.3 and trace elements (mg/l): FeSO4.7H2O, 0.5; MnSO4.4H2O, 1.6; ZnSO4.7H2O, 1.4 and CoCl2.6H2O, 20.0 and Tween-80, 0.1% (v/v) at pH 5.5 [23]. The media were autoclaved (1210C for 15 min), inoculated with 5 mL of seven-day fungi suspension (4.6×106 spores/ml) and incubated (28±2°C) for 5 days. Sample was aseptically withdrawn at 24 hr interval, filtered, and process for analysis of cellulase activity.

2.5 Analysis of cellulase activity

Assay for cellulase activities was conducted according to the method of Wood and Bhat [24]. The reaction mixture (0.5 ml of enzyme source, 0.5 ml of 1% carboxyl methylcellulose (prepared in 0.05 M Na-citrate buffer, pH 5.0) was incubated at 50°C for 10 min. The reaction was terminated by the addition of 1.0 ml of 3, 5- dinitrosalicylic acid (DNS), and the contents were boiled for 5 min [25], after which it was allowed to cool and the absorbance was taken at 540nm. The reducing sugar released was measured as described by Khan et al. [26]. A unit of cellulase activity was defined as the amount of enzyme required to liberate 1μmol of glucose per minute under the assay conditions.

2.6 Effect of pH and Temperature on the activity of Cellulase

The optimum temperature of cellulase produced was studied by incubating 0.5 ml of the crude enzyme with 0.5 ml of 1% CMC in citrate buffer (pH 5) at various temperature range (20-80℃), while the optimum pH of cellulase activity by the microbial isolate using SB as the carbon source were evaluated according to the method described by. Briefly, equal volume (0.5 mL) of the crude enzyme and 1% CMC were incubated with 50mM buffers at different pH (3.0 – 10.0) and incubated for 10 mins at 600C. The enzyme activity was estimated by the DNS method.

2.7 Determination of kinetics parameters of cellulase produced from alkaline pre-treated agro-waste

The powdered agro-waste (SB, CC, and PP) were soaked individually in 2% sodium hydroxide solution (NaOH) in the ratio of 1:10 (substrate: solution) and subjected to microwave irradiation at 110W for 200 seconds (Singh et al. 2015). The NaOH was washed out using distilled water until a pH 7 was attained. The Km and Vmax of the cellulase produced from the organism using the pretreated agro-waste as the carbon source were determined using a double reciprocal Lineweaver– Burk plot. Michaelis-Menten equation was used to fit the data for the kinetic constant in a non-linear manner and curve fitting was done by using excel.

2.8 Statistical Analysis

Analysis was conducted in a replicate of 3. Values were analyzed using Statistical Package for Social Science (SPSS) version 21 and presented as means ± SE of the mean. One Way Analysis of Variance (ANOVA) and Duncan’s Multiple Range Test (DMRT) were used for comparison. Data were considered significant at P < 0.05.

3.0 Results

3.1 Identification of cellulase producing organism from soil samples and using agro-waste as the carbon source

A. niger was isolated from the dumpsite, sewage sludge, and plantain decay soil while A. flavus was isolated from sewage sludge and refuse dump site (Figure 1A). Screening for cellulolytic activity on lignocellulose biomasses revealed that the A. niger and A. flavus isolated from the dumpsite and sewage sludge were potential cellulase producers as demonstrated by the formation of distinct zones of clearance around their colonies (Figures 1B, C, D, and E).

3.2 Cellulase activities of microbial isolate using agro-waste as carbon source

A. niger and A. flavus from SB demonstrated significantly higher cellulase activities (p<0.05) when compared with cellulase activities of the organism when CC and PP were employed as the carbon source. Maximum cellulase activities of the organism was achieved after 24 hr of incubation with SB, after which the activities gradually decrease over time. However, the fungi utilizing CC as a carbon source and those presented with PP as the carbon source demonstrated similar levels and patterns of cellulase activities over the 5 days’ incubation periods with maximum activities occurring between 2-4 days of incubation (Table 1).

Table 1: Cellulase activities of microbial isolate using agro-waste as carbon source.

| Cellulase Activities (IU/mL) | ||||||

| DAY 1 | DAY 2 | DAY3 | DAY4 | DAY 5 | ||

| CMS | A. flavus_SW | 51.28±0.45a | 74.99±0.86 b | 71.36±0.67 a | 71.16±0.67 a | 63.44±0.56 b |

| A.flavus_DS | 54.94±0.56 a | 82.42±0.97 b | 77.91±0.84 a | 66.39±0.27 a | 81.48±0.35 c | |

| A. niger_SW | 55.19±0.98 a | 76.22±0.82 b | 93.17±0.52 b | 130.27±2.89 d | 113.72±1.78 d | |

| PP | A. flavus_SW | 109.78±2.95c | 151.49±0.75e | 91.94±0.95 b | 82.48±0.36 ab | 61.93±0.26 b |

| A.flavus_DS | 64.43±0.84 ab | 77.12±0.78 b | 101.88±0.82 c | 143.67±0.86 d | 104.01±0.89 d | |

| A. niger_SW | 53.44±0.24 a | 86.21±0.92 c | 86.20±0.69 ab | 110.07±0.90 c | 82.41±0.47 c | |

| A.NIGER(RDS) | 100.95±1.76c | 141.60±0.06d | 112.69±1.53c | 109.09±1.92 c | 66.82±0.42 b | |

| CC | A. flavus_SW | 70.31±0.25 ab | 73.93±0.64 b | 79.12±0.95 a | 71.25±0.26 a | 67.32±0.87 b |

| A.flavus_DS | 78.68±1.75 b | 73.43±0.67 b | 86.41±0.73 ab | 73.53±0.87 a | 71.48±0.53 b | |

| A. niger_SW | 68.16±0.53 ab | 73.66±0.67 b | 77.11±0.64 a | 104.70±0.36 c | 82.69±0.89 c | |

| A. niger_DS | 50.95±0.68 a | 64.38±0.73 a | 70.83±0.78 a | 79.61±0.78 a | 68.67±0.45 b | |

| SB | A. flavus_SW | 205.03±3.25 d | 123.32±3.75d | 86.16±0.53 ab | 81.38±0.45 a | 50.69±0.89 a |

| A.flavus_DS | 279.37±4.67 d | 228.19±2.85 f | 204.55±2.68 e | 152.11±0.78 | 85.61±0.46 c | |

| A. niger_SW | 302.13±2.56 e | 250.69±5.37g | 143.69±0.63 d | 140.24±0.47 d | 118.13±0.76 d | |

| A. niger_DS | 263.56±3.89 d | 177.38±2.85e | 106.44±1.67 c | 94.52±0.43 b | 65.57±0.90 b |

Data are MEAN ± SEM of triplicate determinations. Values followed by different superscript alphabet are significantly different (p <0.05). A. niger_SW; A. niger from sewage sludge, A. flavus_SW; A. flavus from sewage sludge, A. flavus_DS; A. flavus from refuse dump site, A. niger_DS; A. niger from refuse dump site.

3.3 Optimization of microbial cellulase production from agro-waste carbon source.

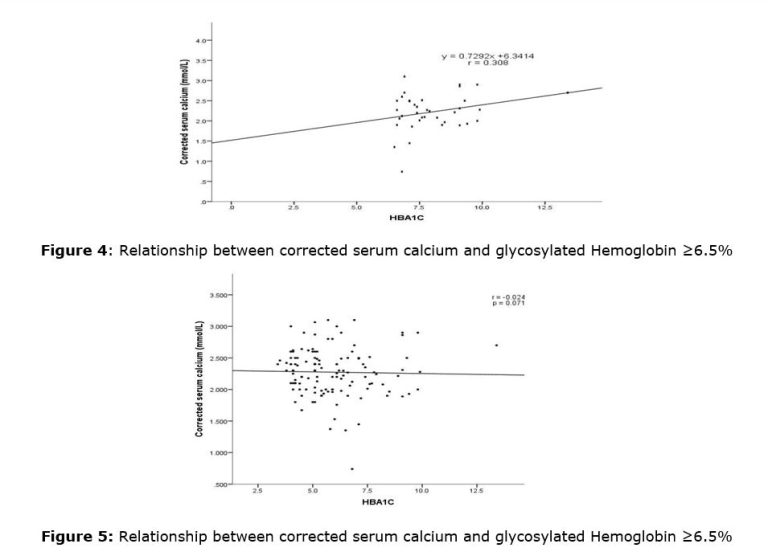

We analyzed the optimum condition for cellulase production by the A. niger using sugarcane bagasse as a carbon source. The results revealed that optimum activity of the microbial cellulase using the SB as the carbon source occur at the temperature and pH of 50oC (figure 2A) and 5 (Figure 2B) respectively.

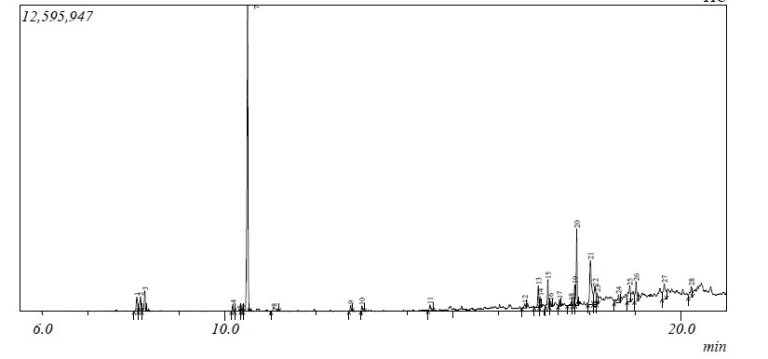

3.4 Kinetics parameters and effect of substrate concentration of microbial cellulase produced from alkaline pre-treated agro-waste

The cellulase activity produced by A. niger isolated from sewage sludge grown under SB, CB, and PP as carbon substrate reaches a maximum with an optimum substrate concentration of 0.3 % (w/v) (Figure 3A). The Km and Vmax of the cellulase activity after transformation of Micheallis Menten plot using double reciprocal plot is shown in the figure 3B and accompanying table

4.0 Discussion

Many microorganisms including bacteria and fungi have been classified as cellulolytic but only a few possess a complete cellulase complex capable of efficient cellulose degradation [6,27]. In the present study, the potential of A. niger and A. flavus to utilized agro-waste as a carbon source for cellulase production was investigated. In addition, the fermentation conditions including the temperature and pH were optimized for cellulase production to determine the suitable condition for minimizing the cost of production and enhance the commercial viability of cellulase production technology.

Fungi produce extracellular cellulases when grown on a suitable carbon source [28]. The cellulases coding genes are induced in the presence of various carbon sources [29]. However, agricultural waste particularly the lignocellulosic biomass has been discovered to be an excellent source for microbial cellulase production [30]. Among the most abundant, available, and assessable lignocellulosic biomass are SB, CB, and PP, and were explored as a carbon source for microbial cellulases production. Among these 3 carbon sources used for microbial cellulase production, sugarcane bagasse was the most suitable carbon source used by A. niger and A. flavus for cellulase production. A maximum activity ranges of 205.03±3.25 and 302.13±2.56 IU/mL was obtained after 24 hr of fermentation with sugarcane bagasse as the carbon source. Production of cellulases by other fungi as Trichoderma spp. using sugarcane bagasse has been widely studied.

Florencio et al., [31] studied the production of endocellulases by different strains of Trichoderma (Trichoderma harzianum and T. reesei RUT C30) using sugarcane bagasse and wheat bran and observed that mutant strain (T. reesei RUT C30) showed higher activity (70.24 UI/g) than the other strains (18–25 UI/g). the cellulase yield obtained in this study is higher than the activities in the present study, and this could be attributed to the species differences of the fungi [32]. Collectively, the present study demonstrated that Aspergillus species when grown under sugarcane bagasse carbon source represent the best strategies for cheap production of cellulase

Generally, pH is an important determinant of enzyme activity [33]. In the present study, the microbial cellulase activity was detected within a pH range of 3-10 with maximum activity at pH 5 (Figure 2B). Studies have reported that the optimal pH for fungal cellulases varies from species to species, however, the values obtained in this study fall within the optimum range (3.0 to 6.0) widely reported [34,35]. Our results are in accordance with earlier reports.

The temperature at which the fermentation was conducted is an important factor that influences the production of microbial cellulase [33]. Herein, the temperature for the cellulase production of Aspergillus species was optimized. Maximum cellulase activities were achieved at 50 o C (Figure 2A). Further increase or decrease in temperature resulted in a decrease in cellulose production. The optimum temperature reported in this study contrast with the findings of Vidya et al. [33], which reported optimum microbial cellulase activity at 30 °C and 28 °C respectively. This discrepancy could be attributed to the species differences of the fungal isolate; Fusarium lini and Trichoderma harziaunum were used in those studies as opposed to the aspergillus species used in this study. However, Imran et al. [36] and Rai et al. [37] reported 50˚C optimum temperature for cellulase activities from A. niger using Bagasse as a carbon source which is in line with the results of the present study. This finding is supported by a previous study which reported that the characteristic of microbial cellulases is largely dependent on the microbial species and strains from which it was derived [38].

5.0 Conclusion

In conclusion, the present study demonstrated that Aspergillus species when grown under sugarcane bagasse carbon source represent the best strategies for cheap and optimum production of cellulase. The optimum temperature, pH, and substrate concentrations were determined as 50∘ C, 5, and 0.3%. This information would be useful for the ideal formulation of media composition for maximum cellulase production by this organism. Further studies were in progress in the purification and application of cellulase in different commercial fields.

Ethics approval and consent to participate: Not applicable

Consent for publication: Not applicable

Competing interests: The authors declared no conflict of interest exist

Funding: The authors’ acknowledgment goes to the Petroleum Technology Development Fund (PTDF) of Nigeria for the grant (PTDF/ED/LSS/PHD/000/0284/19)

Authors’ contributions

All authors participate in research design. Author OOO conducted the research work and write the manuscript. Author EEC supervised the work and revised the manuscript while authors KAA and MAO co-supervised and revised the work. All authors read and approved the final manuscript.

Acknowledgements: The authors would like to appreciate the technical staff of Biochemistry Laboratory Federal University of Technology Minna, for their kind assistances

References

23. Mandels, M.; Weber, J. The production of cellulases. ACS Publications: 1969.

28. Kadam, K.L. Cellulase production. Handbook on Bioethanol 2018, 213-252.